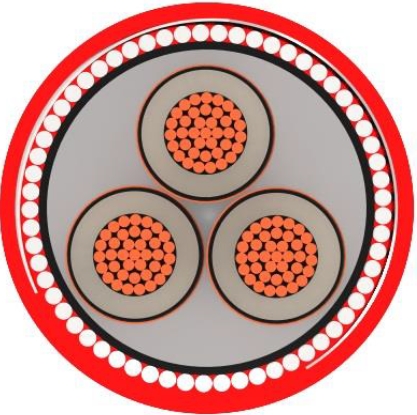

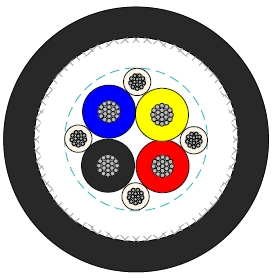

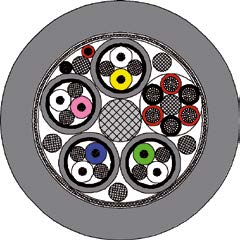

This 0.6/1kV XLPE Insulated PVC Sheathed Steel Wire Armored Power Cable is specifically designed for power transmission in building and industrial facilities, making it an ideal choice for main circuits, secondary circuits, and branch circuits. Whether for main power lines in commercial buildings, power supply for factory production lines, or power distribution networks in industrial parks, it provides stable and reliable power support, ensuring uninterrupted continuous operation of equipment.

Multiple laying methods for complex environments. Supports various flexible laying methods to meet installation requirements in different scenarios. The XLPE insulation layer has excellent electrical insulation performance, reducing the risk of leakage; steel wire armoring enhances mechanical strength, extends cable service life (by over 30% compared to ordinary cables), and reduces long-term maintenance costs; and the PVC sheath is resistant to acid and alkali corrosion, adapts to humid and dusty industrial environments, ensuring long-term stable power transmission.

AS/NZS 5000.1

AS/NZS 3008

AS/NZS 1125

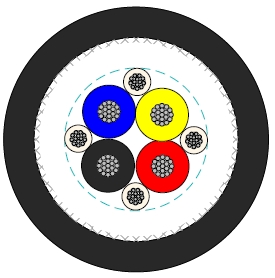

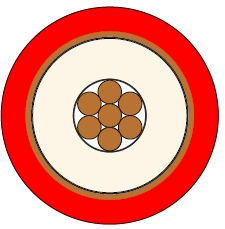

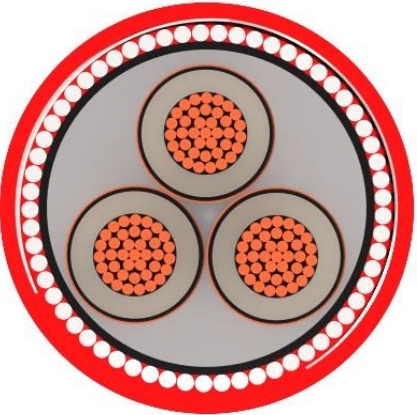

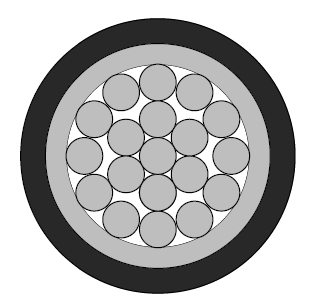

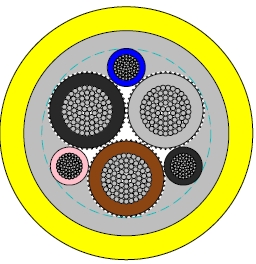

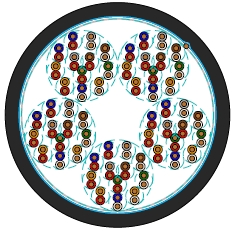

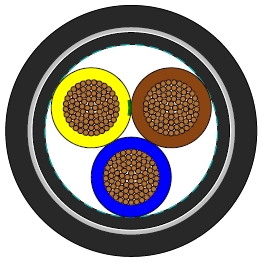

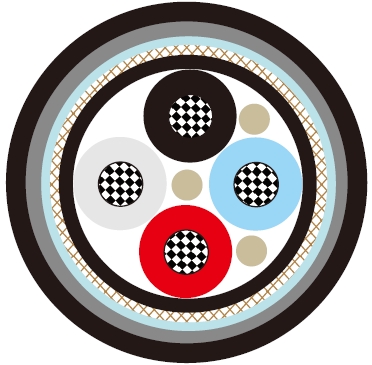

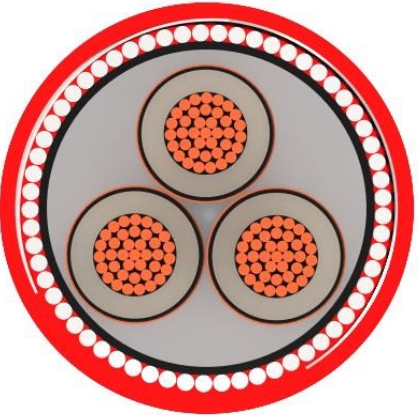

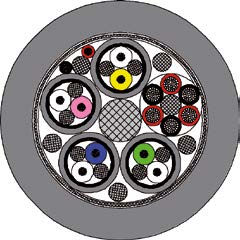

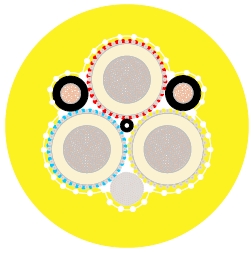

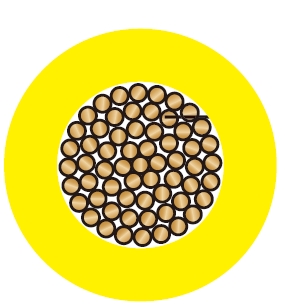

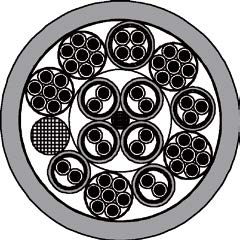

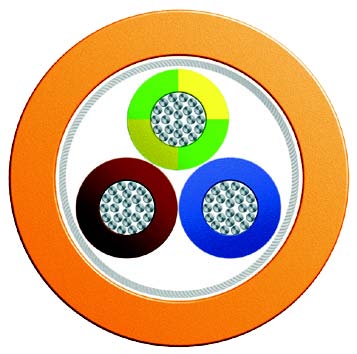

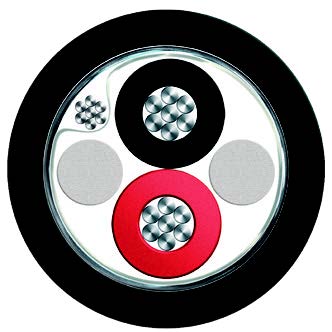

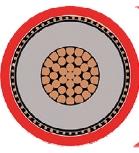

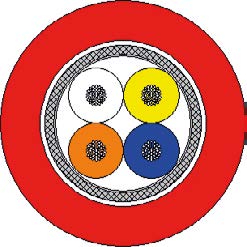

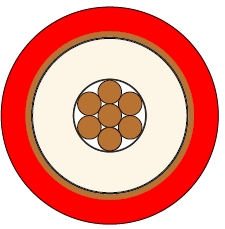

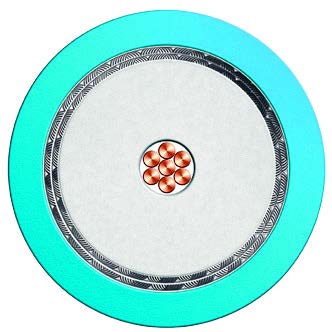

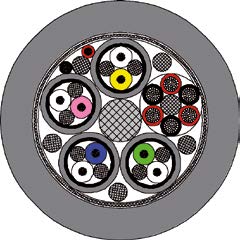

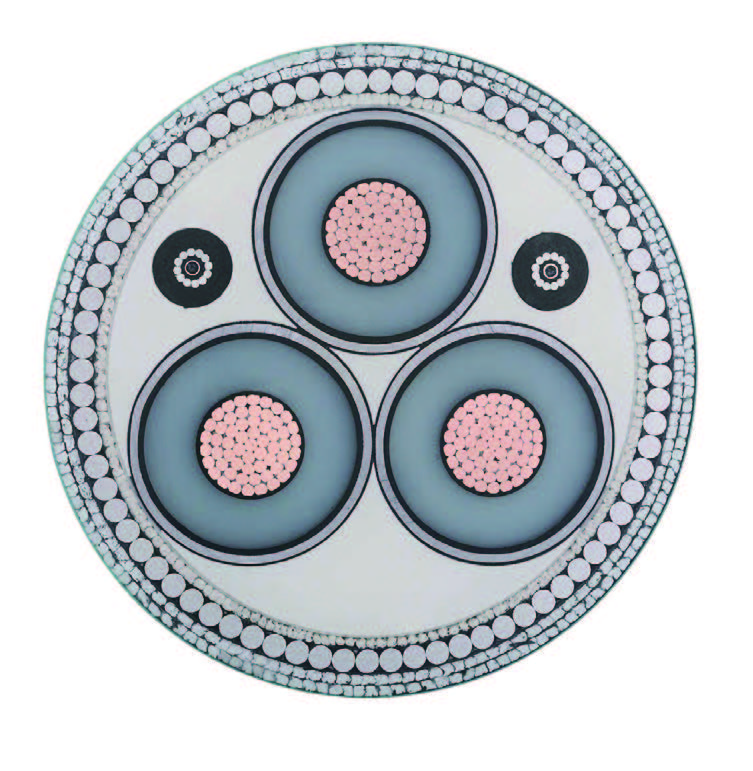

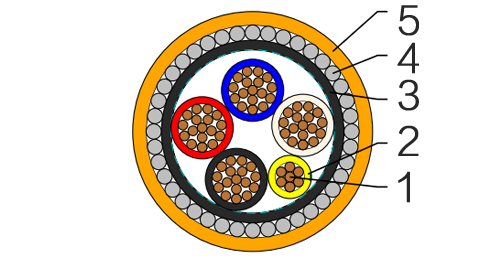

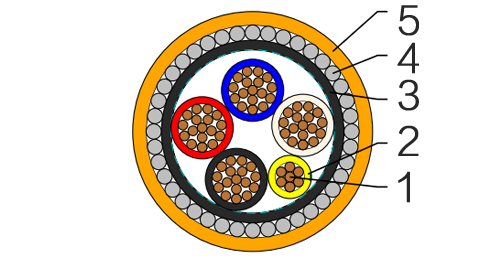

| Conductor | Plain annealed copper. |

| Insulation | XLPE X-90. |

| Insulation colour: | 4C + E - Red, White, Blue, black, Green/yellow |

| Bedding: | Polyvinylchloride compound PVC 5V-90 |

| Bedding colour: | Black |

| Armour: | Galvanised Steel Wire |

| Sheath: | Polyvinylchloride compound PVC 5V-90 |

| Sheath colour: | Orange, other colors are available upon request |

| Conductor | Current Ratings | Electrical Characteristics | |||||

|---|---|---|---|---|---|---|---|

| Nominal Area mm^2 | Unenclosed In Air A | Buried Direct A | Buried In Ducts A | Maximum DC Resistance @20°C Ohm/km | Maximum AC Resistance @90°C Ohm/km | Reactance Ohm/km | Three Phase Voltage Drop @90°C mV/Am |

| 16 | 83 | 110 | 83 | 1.15 | 1.47 | 0.0805 | 2.55 |

| 25 | 110 | 145 | 110 | 0.727 | 0.927 | 0.0808 | 1.61 |

| 35 | 135 | 170 | 135 | 0.524 | 0.669 | 0.0786 | 1.17 |

| 50 | 170 | 205 | 160 | 0.387 | 0.494 | 0.0751 | 0.868 |

| 70 | 215 | 250 | 200 | 0.268 | 0.343 | 0.0741 | 0.609 |

| 95 | 265 | 300 | 240 | 0.193 | 0.248 | 0.0725 | 0.450 |

| 120 | 305 | 345 | 275 | 0.153 | 0.197 | 0.0713 | 0.366 |

| 150 | 350 | 385 | 310 | 0.124 | 0.160 | 0.0718 | 0.307 |

| 185 | 405 | 435 | 355 | 0.0991 | 0.129 | 0.0720 | 0.259 |

| 240 | 480 | 500 | 420 | 0.0754 | 0.0998 | 0.0709 | 0.216 |

| Nom. conductor area mm^2 | Conductor No./ OD | Nom. insulation thickness mm | Nom. earth conductor area mm^2 | Nom. earth conductor insulation thickness mm | Nom. diameter over bedding mm | Armour diameter mm | Nom. overall diameter mm | Approx. mass kg/km |

|---|---|---|---|---|---|---|---|---|

| 16 | 7/1.70 | 0.7 | 6 | 0.7 | 19.4 | 1.6 | 26.3 | 1725 |

| 25 | 7/2.14 | 0.9 | 6 | 0.7 | 22.7 | 1.6 | 29.6 | 2335 |

| 35 | 7/2.65 | 0.9 | 10 | 0.7 | 24.4 | 1.6 | 31.5 | 2605 |

| 50 | 19/1.89 | 1.0 | 16 | 0.7 | 27.8 | 2.0 | 36.5 | 3860 |

| 70 | 19/2.24 | 1.1 | 25 | 0.9 | 33.4 | 2.0 | 41.8 | 5135 |

| 95 | 19/2.65 | 1.1 | 25 | 0.9 | 36.9 | 2.5 | 45.8 | 5900 |

| 120 | 19/2.94 | 1.2 | 35 | 0.9 | 38.1 | 2.5 | 51.7 | 9090 |

| 150 | 19/3.28 | 1.4 | 50 | 1.0 | 42.2 | 2.5 | 56.9 | 10410 |

| 185 | 37/2.65 | 1.6 | 70 | 1.1 | 52.2 | 2.5 | 63.1 | 11600 |

| 240 | 37/2.94 | 1.7 | 95 | 1.1 | 58.8 | 2.5 | 70.1 | 14700 |